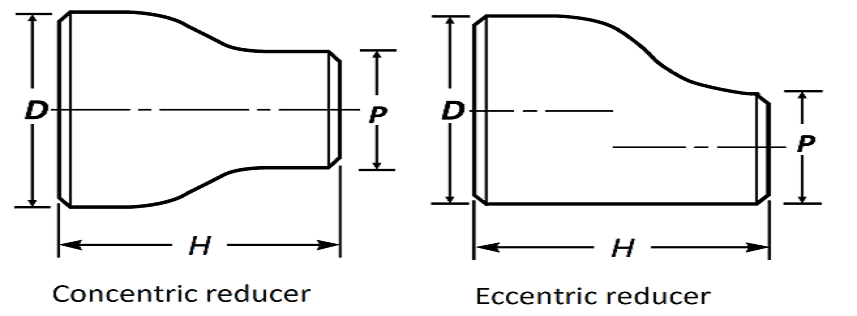

Incoloy® 825 Reducing Tee Stockholder, Incoloy 825 Pipe Elbow Stockists, 8D, 825 Incoloy Butt weld Fittings, Nickel Alloy 825 Butt Weld Pipe Fittings, 825 Incoloy Alloy Buttweld Fittings, Incoloy Grade in 825 R=1D, 825 Nickel Alloy Reducing Cross Dealers in India, ASME B16.28 Incoloy Alloy 825 Equal Cross Dealer, Incoloy® Alloy 825 Butt weld Pipe Cross, ASTM B366 Incoloy 825 Stub End Stockists, Nickelvac® 825, Incoloy® Unequal Cross Stockholders, 825 Incoloy® Alloy B366 Concentric Reducer, MSS SP-79 Incoloy® 825 LR Elbow, Nicrofer® 4221), UNS N08825 Incoloy Unequal Tee, 3D, MSS-SP-43 825 Short Radius Elbow, Incoloy 825 - UNS N08825 Common Trade Names ( Incoloy 825®, GOST ЭП703 Incoloy® 825 Buttweld Reducers, 5D, Incoloy 825 Pipe Fittings, Incoloy 825 Buttweld Pipe Cap, ASTM B366 Incoloy® 825 Seamless Pipe Elbow, 6D, Incoloy® Alloy 825 Buttweld Elbow, Incoloy® 825 Pipe Fittings, 825 Incoloy 45Deg. Pipe Elbow, Alloy 825 Pipe Fittings, ANSI B16.9 Incoloy 825 SR Elbow, Alloy 825 90° Degree Elbow, Incoloy® JIS NCF 825 180 Degree Elbow Traders, 10D Butt weld Elbow, 2D, 825 Alloy Fabricated Tee Supplier, Supplier of Incoloy 825 Concentric Reducer, Cheap Incoloy 825 Pipe Fittings, 825 Incoloy Alloy ASME SB366 Long Radius Elbow, Werkstoff No 2.4858 Nickel Alloy Buttweld Tee, 825 Incoloy® Alloy Butt weld Pipe Fittings, Incoloy 825 Equal Tee, Manufacturer of Incoloy 825 Eccentric Reducer Traders, 825 Incoloy® Butt weld Seamless Pipe Fittings Stockholders, Exporters of Incoloy® Alloy 825 Welded Pipe Fittings, SB366 Alloy 825 End Pipe Cap Wholesaler, Supplier of Incoloy® 825 End Cap.