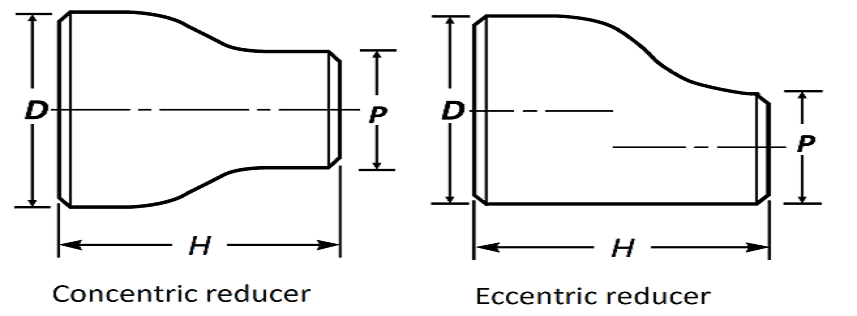

stainless steel 904l short radius elbow – sr elbow, price of lap joint stub ends stainless steel 904l, ss 904l welded elbow, schedule 10 stainless steel 904l pipe fittings, stainless steel 904l long radius elbow – lr elbow, aisi 904l pipe fittings, ss 904l long radius bend, stainless steel 904l reducer, 904l ss piggable bend, stainless steel 904l welded tee stockholder, asme sb 366 stainless steel 904l 5d elbow, ss 904l pipe nipple exporter in india, ss 904l seamless pipe elbow, astm b366 wp904l 180° long & short radius elbow, grade 904l stainless steel butt weld collar, astm b366 wp904l stainless steel butt weld pipe fittings dimensions, astm b366 ss 904l buttweld fittings manufacturer in mumbai, stainless steel 904l buttweld fittings manufacturers in india, ss 904l welded pipe fittings, buy best and high quality stainless steel 904l buttweld fittings at competitive price, ss 904l 90 deg long radius elbow, type 904l ss pipe fitting price, astm b366 wp904l fittings supplier in india, sus 904l butt weld pipe fitting, stainless steel 904l bend, ss 904l 3d elbow stockholder, ss 904l 1d elbow dealers, ss 904l buttweld pipe fittings, ss 904l seamless pipe fitting, 904l stainless steel 45° short radius elbow, astm b366 wp904l buttweld fittings price list, stainless steel 904l schedule 40 buttweld fittings, 904l stainless steel straight tee traders.