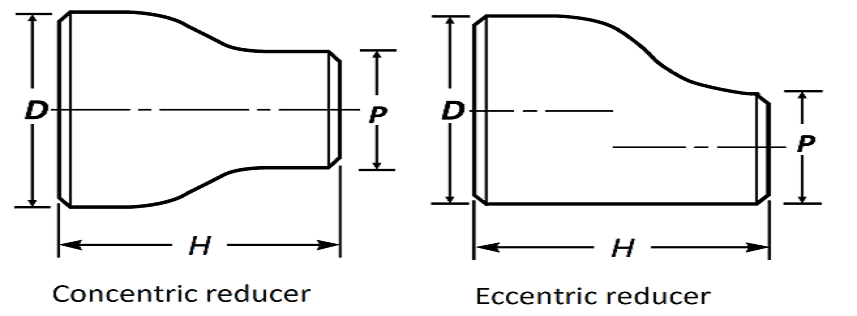

SS 316L seamless fittings, seamless elbow, ss fittings manufacturer, ss 316L weldable pipe fittings, ss pipe fittings catalogue, asme sa403, Top Quality Stainless Steel 316L Reducer, High quality stainless steel pipe fittings Manufacturers, Special Stainless Steel 316L Pipe Fittings, seamless pipe fittings, buy stainless steel 316L pipe fittings, seamless buttweld fittings, ss 316L elbow price, astm a403 standard pdf, stainless steel 316L fittings prices, Elbow 90 Degree Manufacturer, Stainless Steel Fittings, astm a403 fittings, stainless steel pipe fittings manufacturers in india, ANSI 316L stainless steel pipe fittings, astm a403 fitting dimensions, Competitive Price Factory Customized Stainless Steel 316L Pipe Fittings, astm a 403 stainless steel fittings, ss pipe fittings manufacturer, a403 material, 6 inch welded stainless steel 316L pipe fittings, schedule 10 SS 316L Fittings, ss pipe fittings price list, astm a403 elbow, ss 316L elbow price, ss 316L Schedule 40 pipe fittings, Steel Pipe Fittings, ss pipe fittings suppliers, ASTM A403, astm a403m, astm a403 chemical composition, astm a403 fittings, ss elbow dimensions.